Outstanding service | Exclusive pricing | Industry expertise

TANKS, BUNDS AND CABINETS

Discover our custom-designed PP (Polypropylene) and PE (Polyethylene) tanks, bunds, and cabinets, tailored to meet the specific needs of your industrial and chemical applications. These solutions are crafted from high-quality virgin materials known for their exceptional chemical resistance, durability, and strength. Ideal for environments where standard solutions do not meet your requirements, our non-standard tanks, bunds, and cabinets can be customized in size, shape, and features to suit your precise needs. Whether you need reliable storage, spill containment, or secure protection for control systems, these bespoke solutions provide robust, long-lasting performance in even the harshest conditions. Perfect for chemical storage, processing, and safe handling, choose our PP and PE products for your critical operations.

-

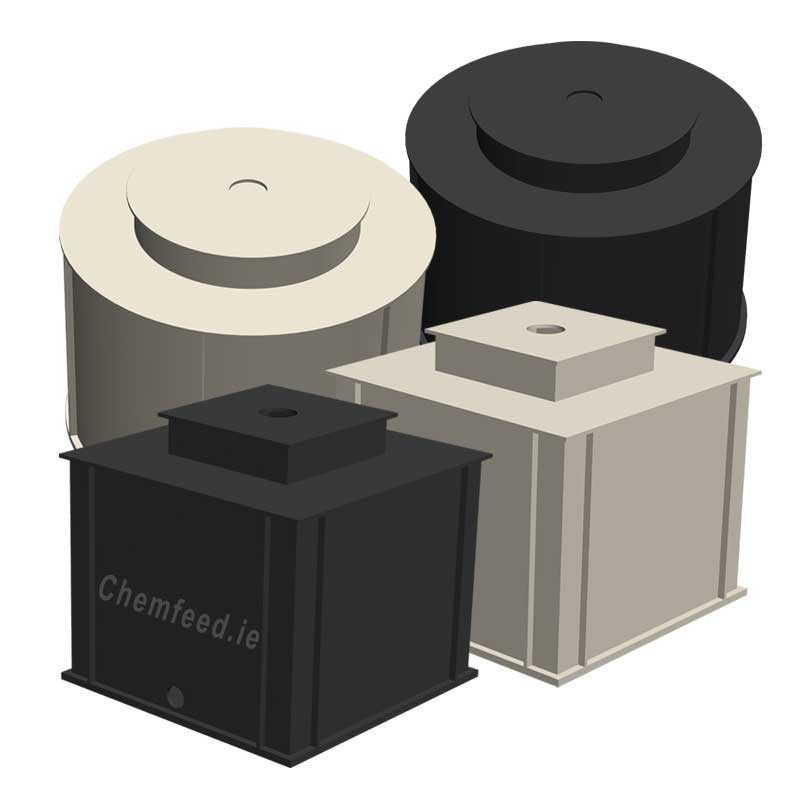

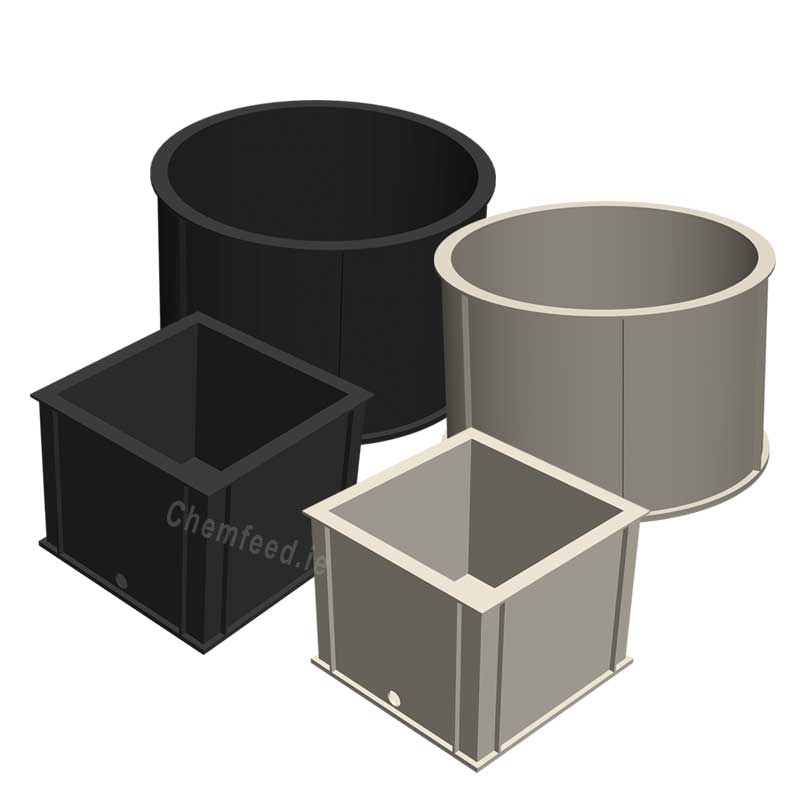

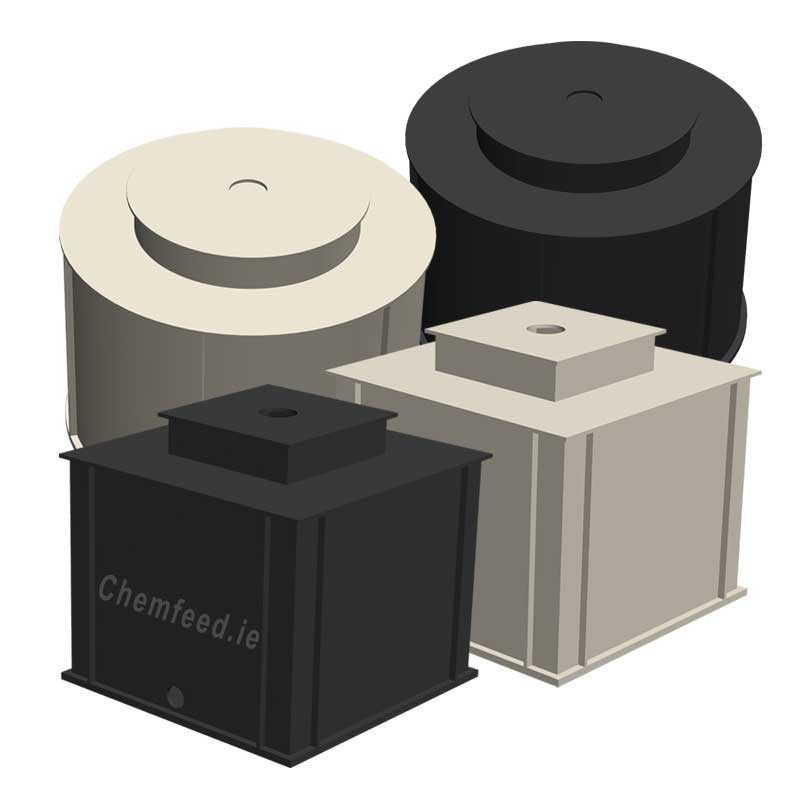

STANDARDS TANKS AND 110% BUNDS

The Tanks and 110% Bunds collection of high quality polyethylene offers reliable...

-

NON-STANDARDS TANKS

Discover our custom-designed non-standard tanks made from high-quality Polypropylene (PP) or Polyethylene...

-

CONTROL CABINETS

Explore our range of Polypropylene (PP) and Polyethylene (PE) control cabinets, specifically...

How Plastic Tanks Are Made

We can manufacture custom tanks to match your specifications. You can specify the material, dimensions and we will work you to design a tank to suit your criteria. We confirm the design with our dedicated software. All our tanks are CE marked and plated with the design parameters.

Why Choose Plastic for Tanks?

Plastic tanks are incredibly versatile because the material is chosen so that it is compatible with the contents. Many chemicals can cause corrosion in metal tanks, whereas plastic is both a more cost-effective solution and less reactive. There are various types of plastic available, each offering different characteristics for your specific project. Plastic is lightweight and durable material. It is more flexible in terms of design than many other options. In fact, the only real limitations for plastic tanks are extreme temperatures and chemical resistance charts.

Who Uses Plastic Tanks?

Almost every industry requires plastic tanks for something. They are widely used in industry. Liquids need to be stored and transported across a wide range of sectors, including:

- Agriculture

- Petrochemicals

- Gas

- Oil

- Water Treatment

- Chemicals

- Food

- Beverage

- Recycling

- Manufacturing

- Electroplating

- Biomedical

- Pharmaceutical

- Semiconductor

What Are the Best Materials?

Each type of plastic comes with its own set of characteristics that may either make it the perfect choice for your tank or unsuitable. It’s always best to begin by advising us of your proposed application. The most commonly used plastics include:

Polyethylene

Polyethylene is the most widely used plastic globally, and for good reason. It has a consistent working temperature of up to 180°F and comes in three grades:

- Low density

- High density

- Ultra-high molecular weight

Polyethylene is a top-tier thermoplastic capable of withstanding both chemical and physical stress. It can even be used to store food. Its other advantages include:

- Excellent mechanical properties

- High stiffness

- Superior impact resistance at low temperatures

- Impressive environmental stress cracking resistance

Polypropylene

Polypropylene, often referred to as the "steel" of plastics, is the second most common plastic. It has a working temperature of up to 200°F. Some of its advantages for tank construction include:

- Superior thermal insulation properties

- High tensile strength

- A semi-crystalline structure that makes it particularly resistant to chemical damage

- Strong and stable

- Excellent manufacturability

- Cost-effective

- Readily available

How Are They Customised?

You may find that the off the shelf storage container you need doesn’t exist yet. That’s why we offer a customised service for plastic tanks. The possibilities are endless—and we will work with you to design the best possible solution.